2025-11-18 In the world of plastic injection molding, 2K (two-shot) overmolding is a game-changer. It allows us to combine a rigid substrate with a soft, flexible TPE/TPU material in a single, automated cycle, creating products with enhanced grip, aesthetic appeal, and functionality.

But one of the most common and critical questions designers and engineers face is: "How thick should the soft-touch layer be?"

The answer isn't a single number. It's a carefully balanced range, influenced heavily by the materials you choose. Get it right, and you have a perfect, durable bond. Get it wrong, and you face delamination, sink marks, or incomplete filling.

Let's dive into the core principles and find that "Goldilocks Zone" – not too thick, not too thin, but just right.

Read More

2025-11-17 In the world of product design, user experience is king. And few manufacturing techniques enhance user experience as directly as overmolding (also known as two-shot molding). This process bonds a soft, often rubber-like material onto a rigid plastic substrate, creating products that are comfortable to hold, easy to grip, and visually appealing.

Think of the satisfying feel of a high-end power tool, the secure grip of your electric toothbrush, or the durable yet soft case protecting your smartphone. These are all triumphs of overmolding.

But the success of any overmolded product hinges on two critical choices: the materials and their hardness. Get this right, and you create a product that feels premium and functions flawlessly. Get it wrong, and you face delamination, premature wear, or a simply unpleasant feel.

Read More

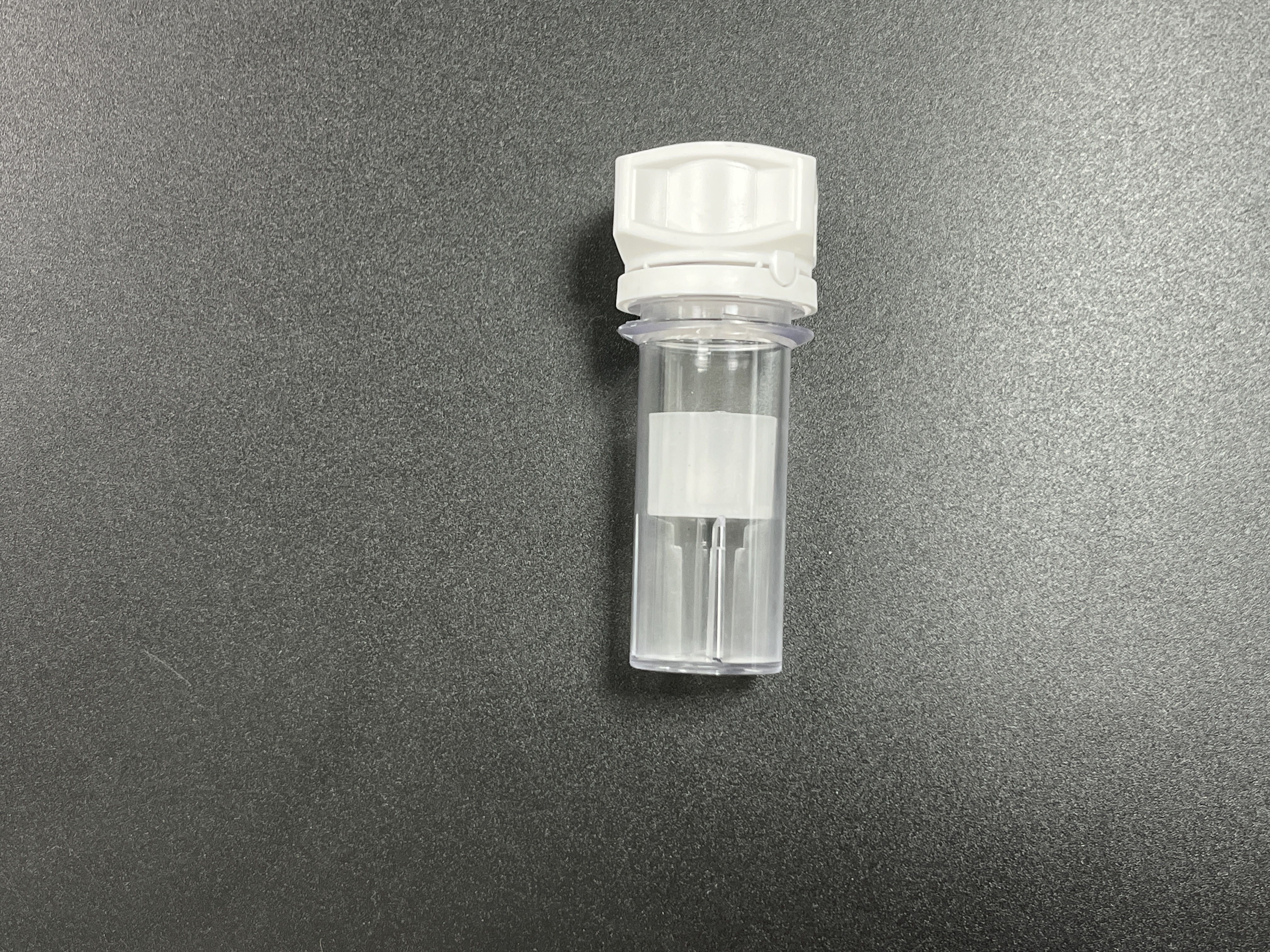

2025-11-17 In the medical industry, sterilization is a cornerstone of patient safety and infection control.

Read More

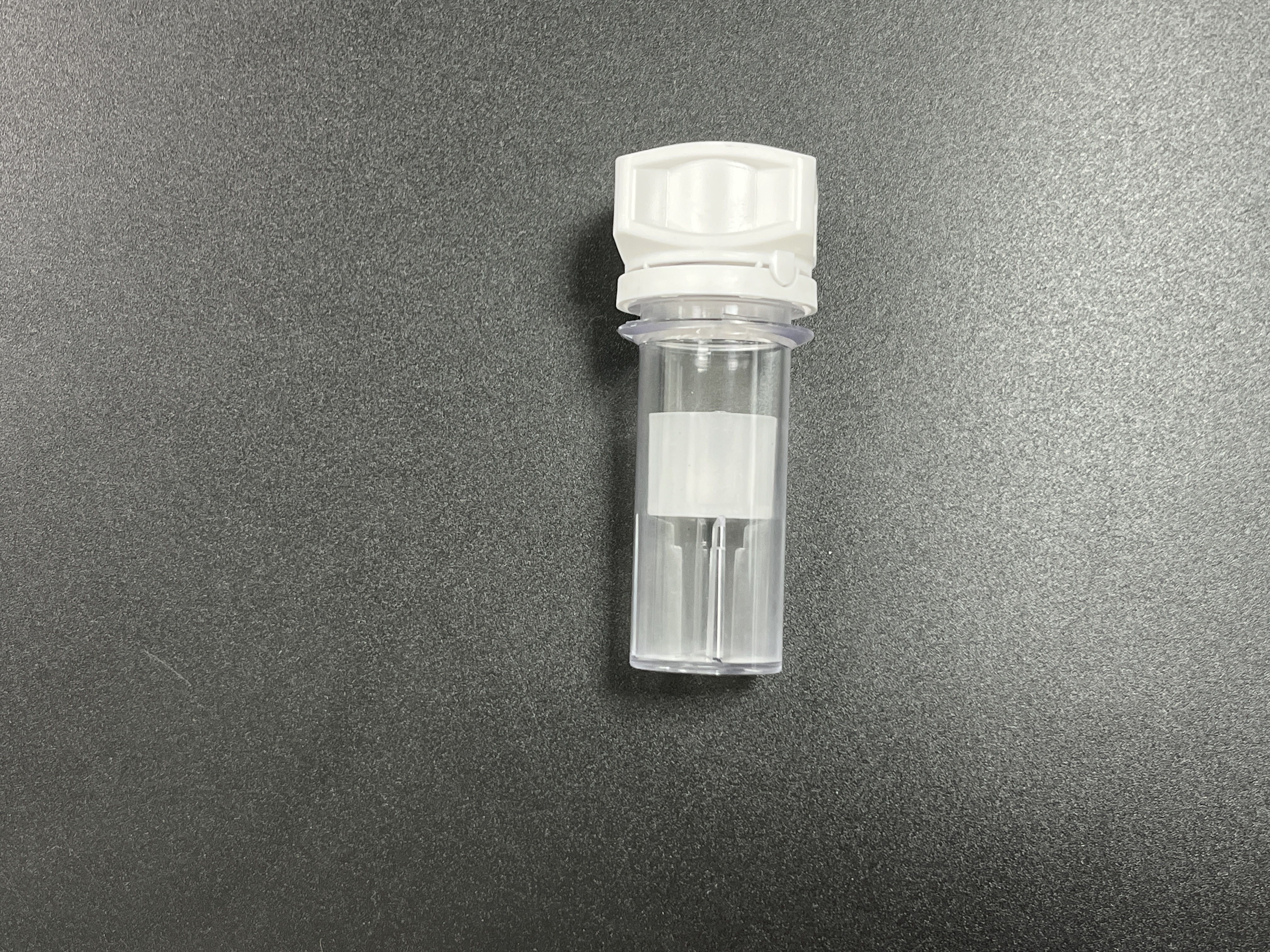

2025-11-14 In the world of injection molding, efficiency is king. Any process that can be automated not only speeds up production but also enhances consistency and reduces costs. When it comes to plastic parts with screw threads—like bottle caps, cosmetic containers, or medical devices—the thread forming mold (often colloquially called a "rotating core" or "unscrewing" mold) is the undisputed champion of automation.

But what exactly is it, and how can you leverage its power for your projects? Let's dive in.

Read More

2025-11-13 So, the moment of truth has arrived: the first trial run of your brand-new injection mold. It's an exciting step, but it can quickly turn frustrating when the parts coming out aren't perfect. Don't worry—this is completely normal! The entire purpose of a trial run (or "T1") is to identify and solve these very problems.

Think of it as a diagnostic check for your mold and process. Today, we'll break down the most common issues you'll encounter during mold trials, their root causes, and the practical steps you can take to fix them.

Our Core Problem-Solving Philosophy: "Soft" vs. "Hard"

Before we dive in, remember this golden rule: "First adjust the soft, then modify the hard."

"Soft" refers to the process parameters: temperature, pressure, speed, and time.

"Hard" refers to the mold itself: its geometry, gate size, cooling channels, and vents.

Read More

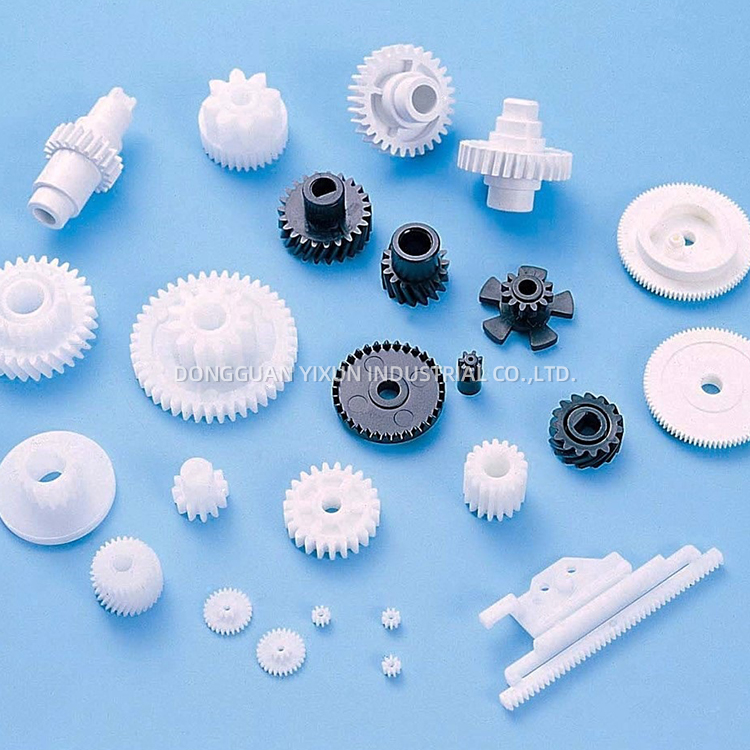

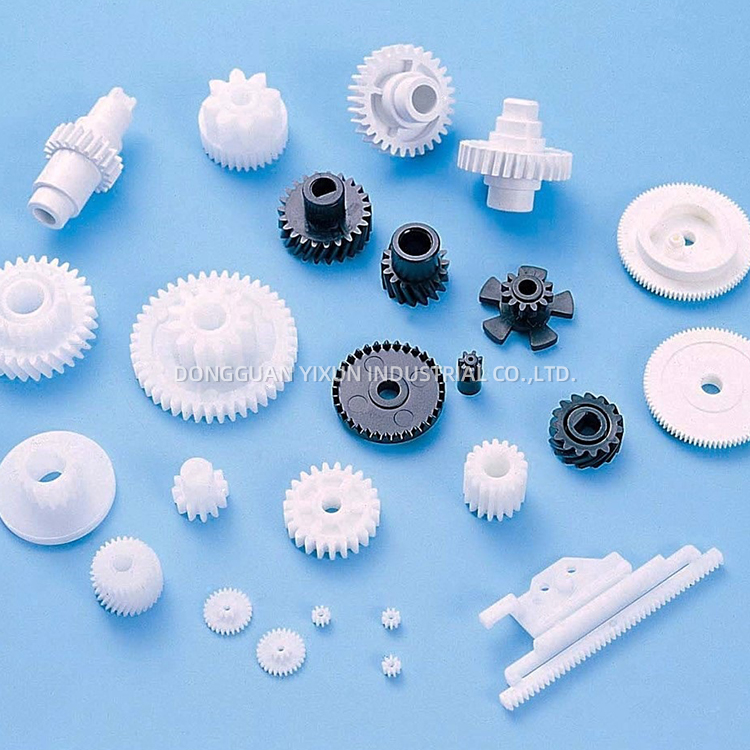

2025-11-12 In the world of precision manufacturing, plastic gears are ubiquitous, found in everything from automotive systems to smart home devices. Their performance hinges on one critical factor: the accuracy of the injection molds that create them. Ensuring these molds meet exact specifications requires a sophisticated approach to measurement. This blog explores the essential tools and methodologies for verifying plastic gear injection molds, guaranteeing the production of high-quality, silent, and efficient gears.

Read More

2025-11-11 Blog Outline:

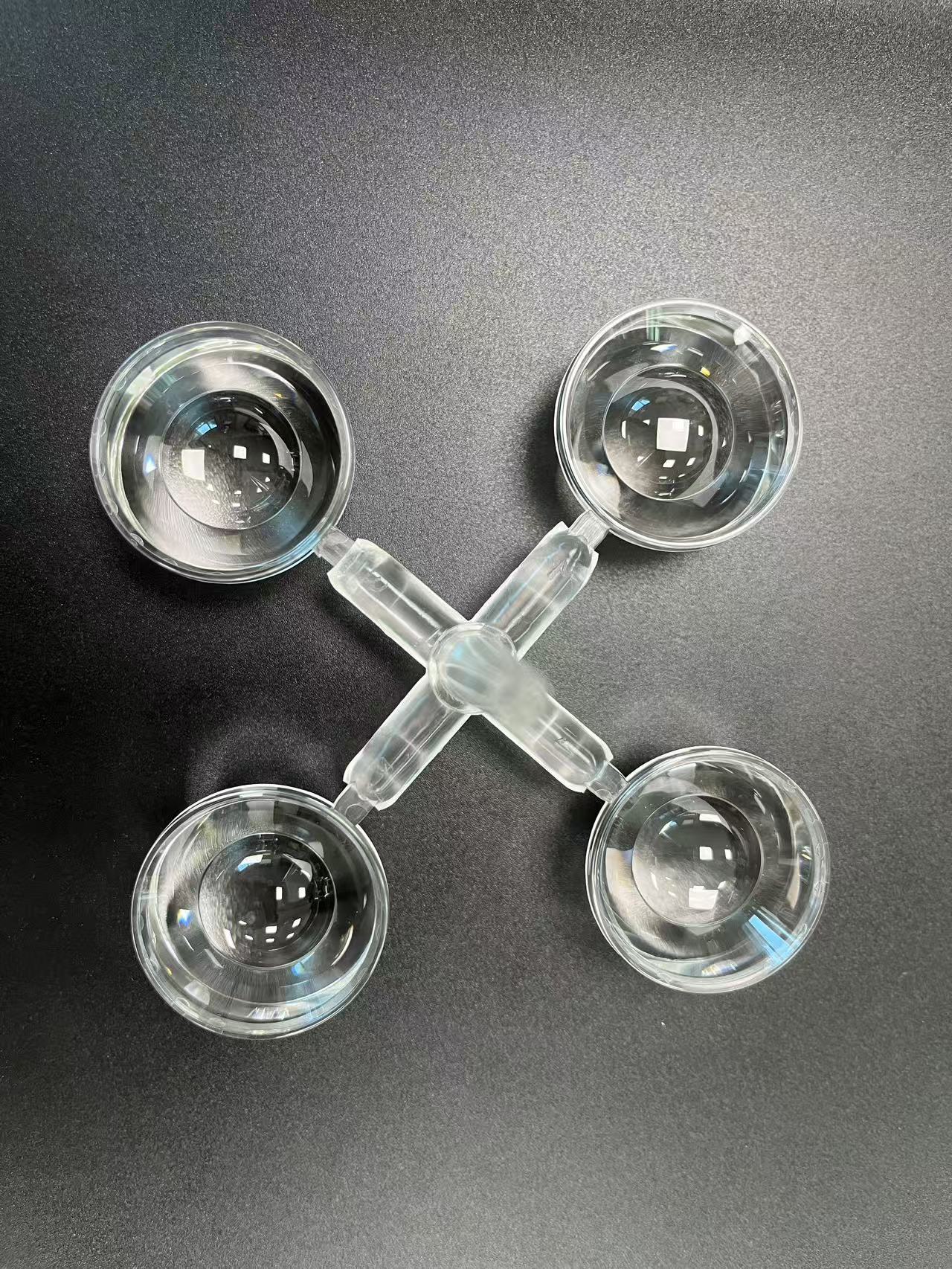

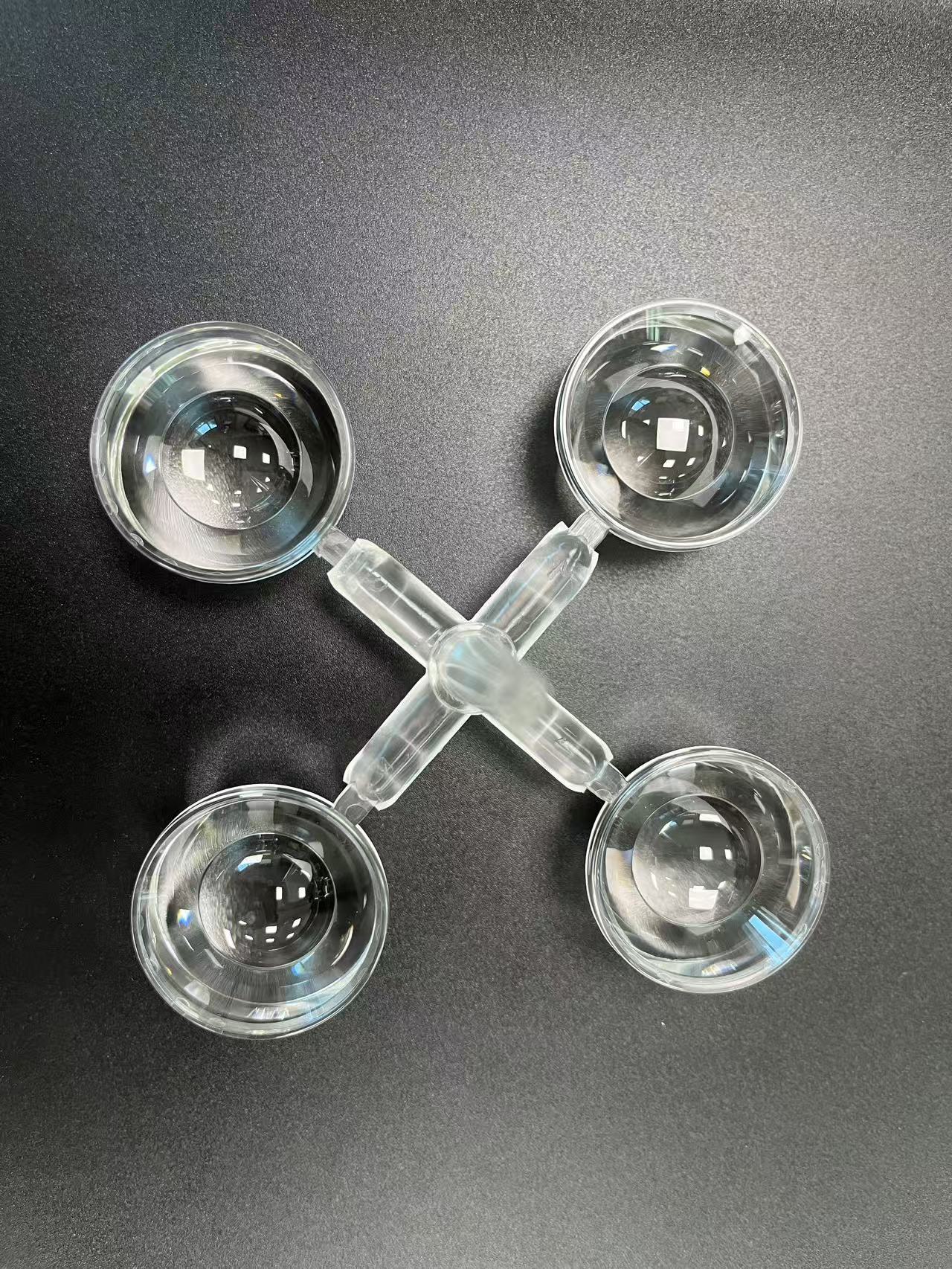

Introduction: Highlighting the ubiquitous nature of injection-molded optical parts and the critical role of the mold.

The Core Challenge: Explaining why manufacturing these molds is more demanding than standard mold making.

The Manufacturing Blueprint: A detailed breakdown of the four key phases in creating a high-precision optical mold.

The Non-Negotiable Requirements: Focusing on the essential needs for the production environment and injection molding process.

Conclusion: Summarizing the synergy of technology and craftsmanship required for success.

Read More

2025-11-11 The global trade landscape is undergoing a significant transformation, driven by a series of recent updates to U.S. tariff policy. For businesses, supply chain managers, and market analysts, staying informed about these changes is not just beneficial—it's essential for strategic planning and risk mitigation. Over the past two months, key developments have included adjustments to the broad tariff framework, the imposition of new punitive tariffs on specific goods, and critical legal challenges that could reshape the entire system. This blog post provides a clear, structured overview of these recent shifts, offering actionable insights into how these updated import regulations may affect international trade flows and business operations.

Read More

2025-11-10 In the high-stakes world of injection molding, two questions fundamentally shape the profitability of any project: "How long will the mold last?" and "How many parts will it produce per cycle?" The answers lie in a strategic balance between tooling life and cavity count.

While these concepts are intertwined, their importance shifts dramatically depending on your production volume. Let's dissect the factors at play and outline the winning strategies for both high-volume and low-volume production.

Read More

2025-11-10 In the world of injection molding, we often focus on what we can see—a part’s surface finish, its color, its dimensions. But for countless components, from automotive fuel systems to medical devices, the most critical quality is one we can't see: a perfect seal.

A tiny, invisible leak can lead to product failure, safety hazards, and costly recalls. So, how do we ensure that a plastic part is truly sealed? The answer lies in a robust and well-designed leak testing process.

Let's dive into the most common methods and the crucial standards that define success.

The Arsenal of Leak Detection: From Bubbles to AI

There isn't a one-size-fits-all solution. The choice of method depends on the required sensitivity, production volume, and cost.

Read More