2026-02-03 In the high-stakes world of injection molding, downtime is the enemy. A mold on the bench is a line not producing. Among the most frequent culprits of unplanned stops are three common types of physical damage: broken pins, wear, and chipping.

Understanding how to properly diagnose and repair these issues is not just a maintenance task—it's a critical skill for maximizing productivity and protecting a valuable asset. Here’s your practical guide.

Read More

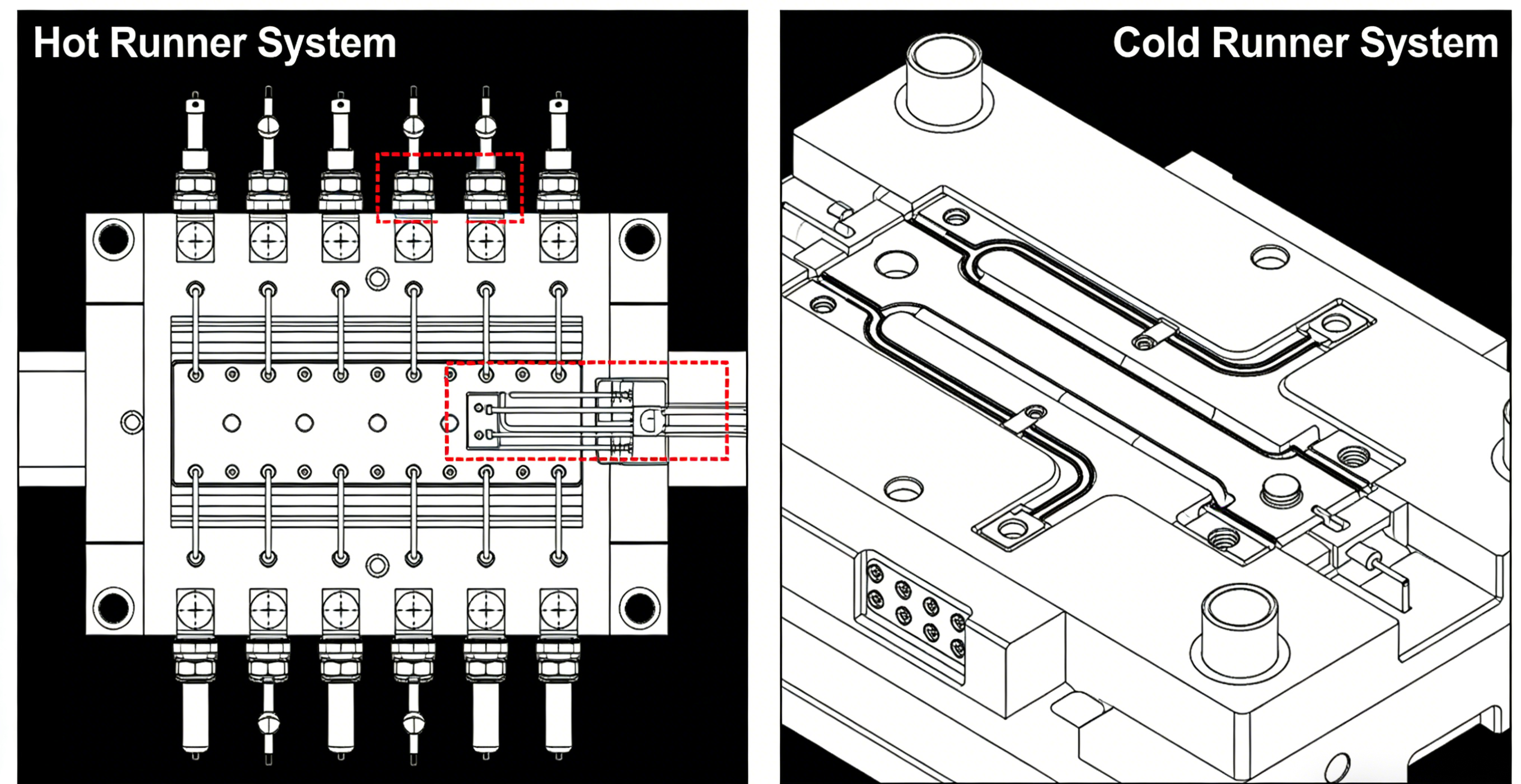

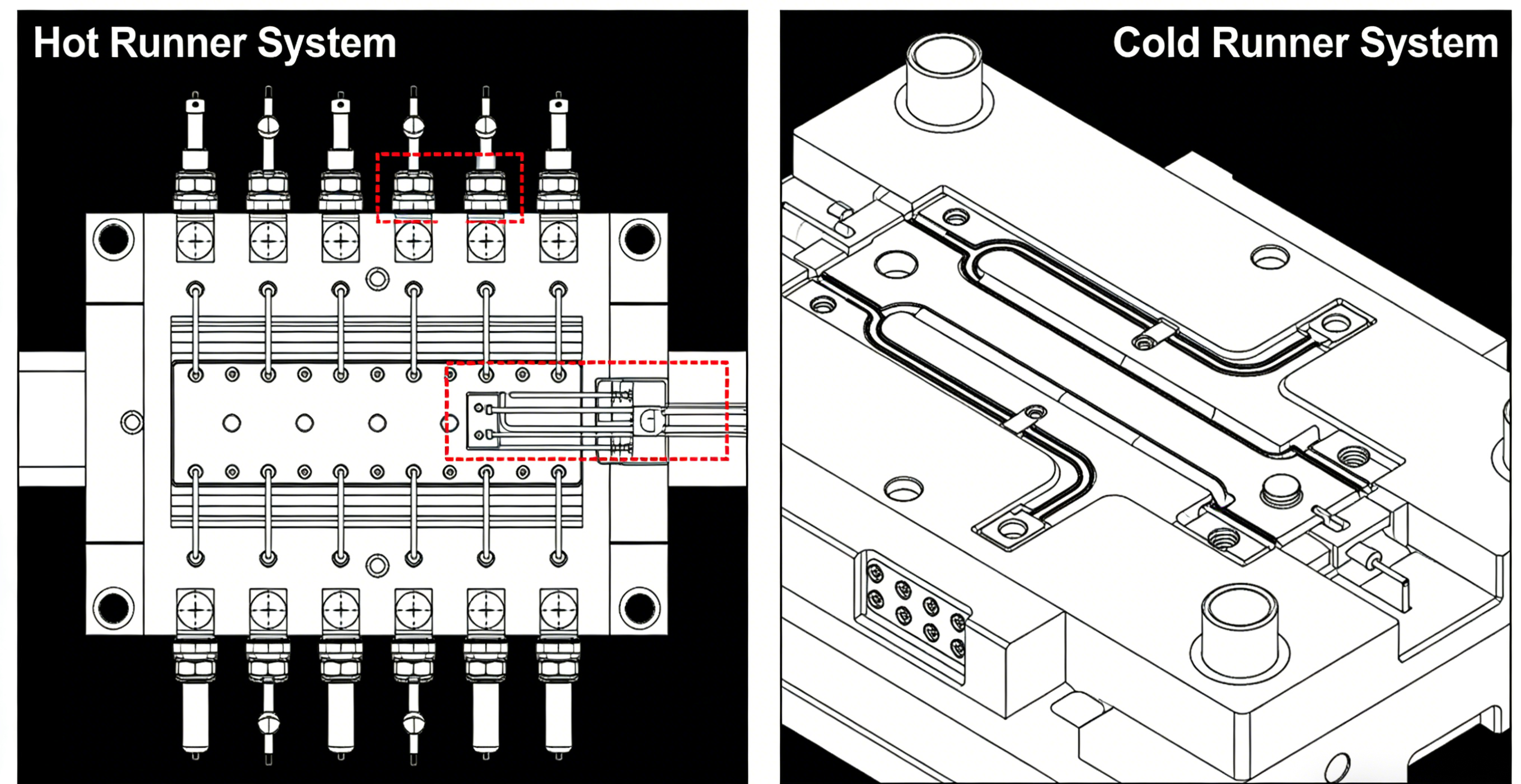

2026-02-02 If you've been around injection molding, you've heard of hot runner molds. They're often described as the "premium" option—significantly more expensive than traditional cold runner molds, yet overwhelmingly preferred for high-volume production. Why is there such a paradox?

Let's demystify hot runner technology by answering two fundamental questions.

Read More

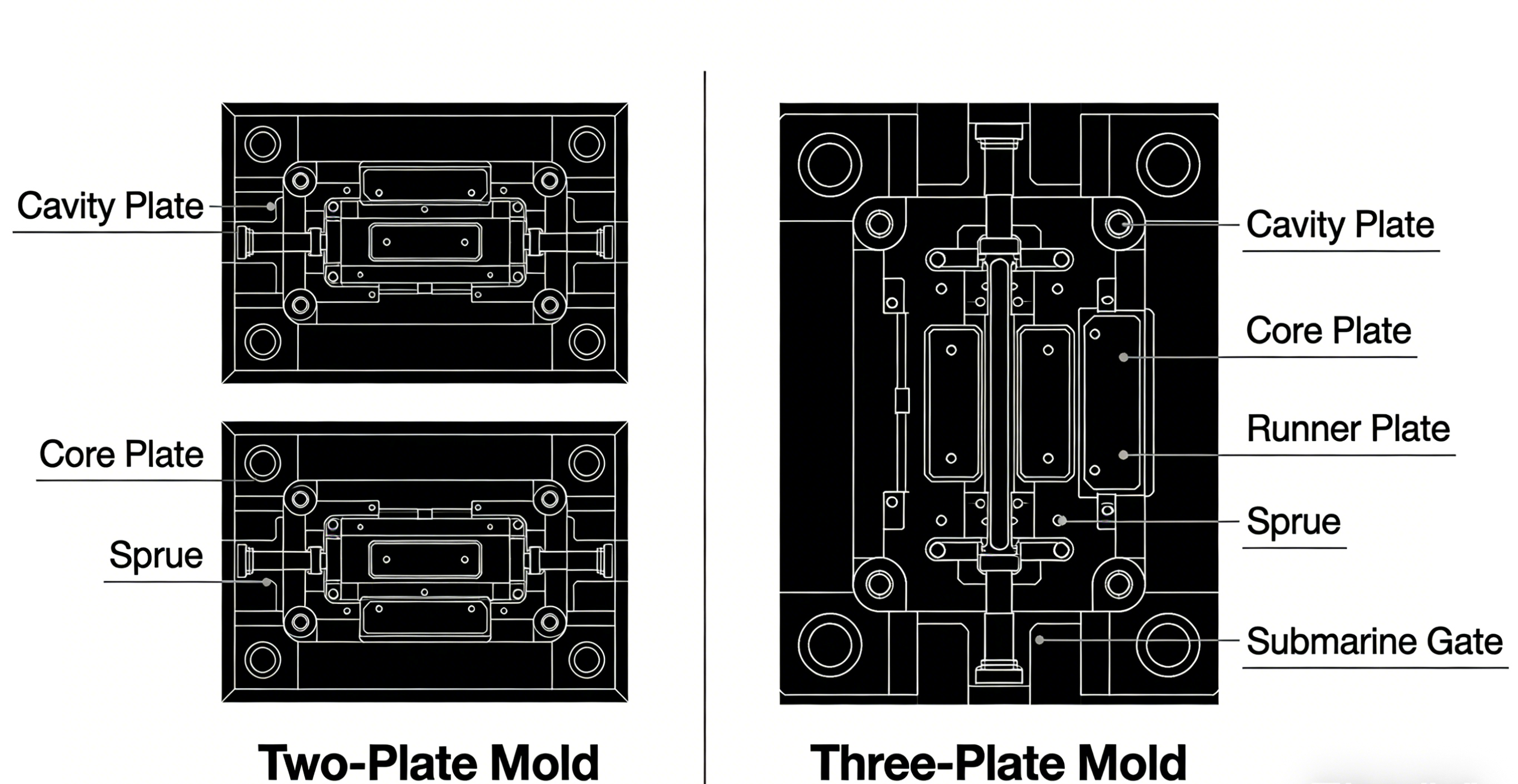

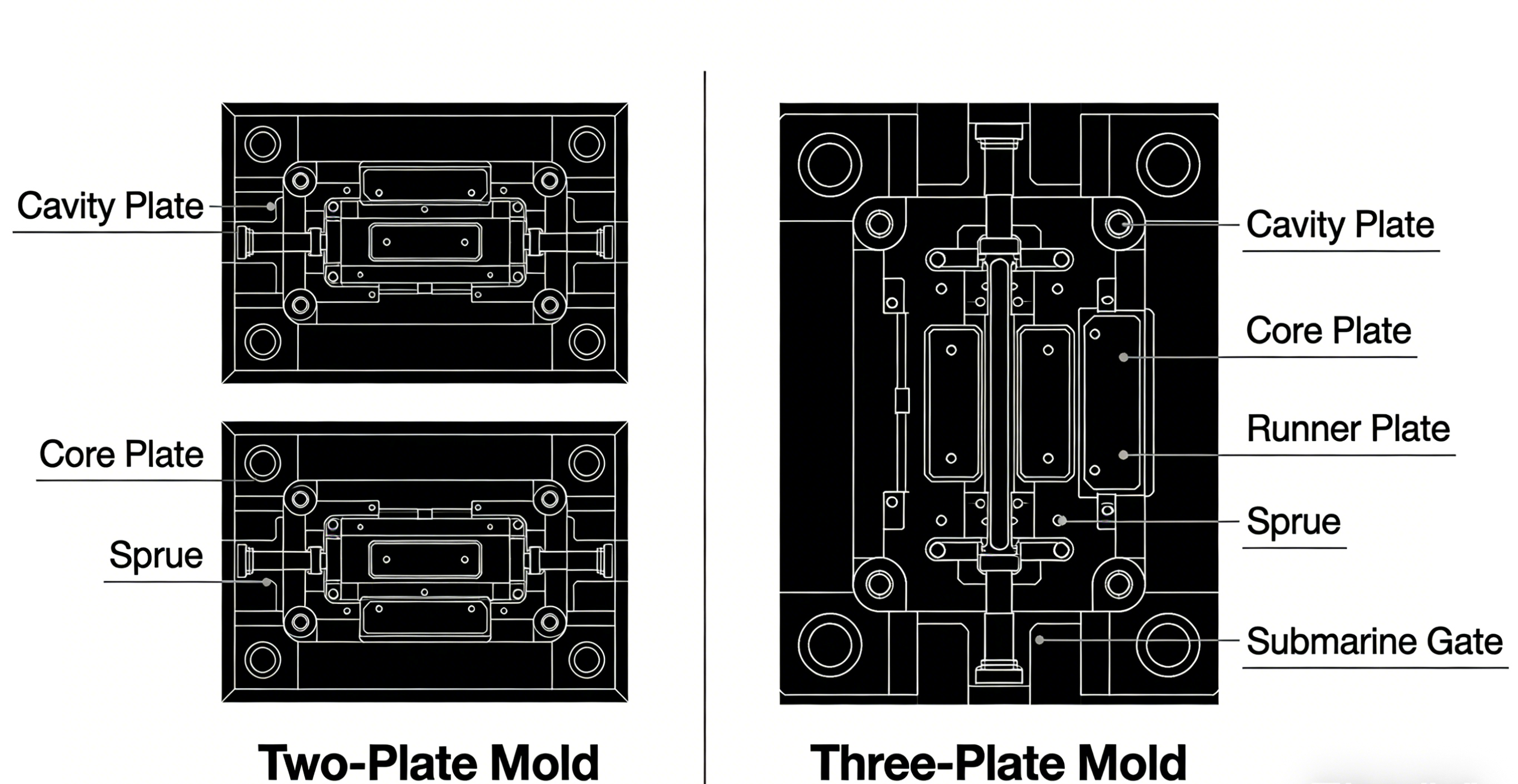

2026-02-02 If you're involved in plastic part design, procurement, or manufacturing, you've likely heard the terms "two-plate mold" and "three-plate mold." While they both make plastic parts, the choice between them fundamentally impacts cost, part appearance, and production efficiency.The core difference lies

Read More

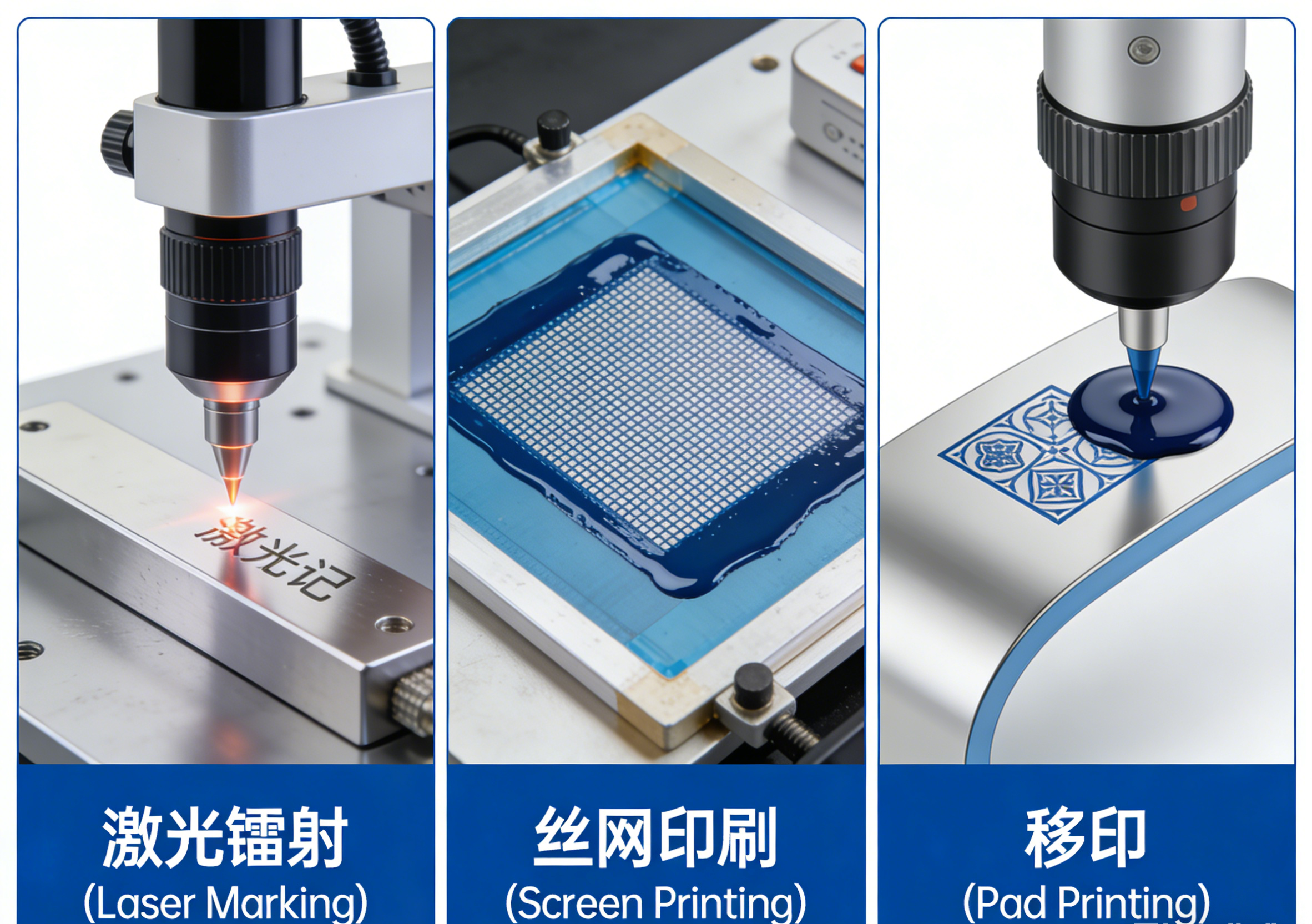

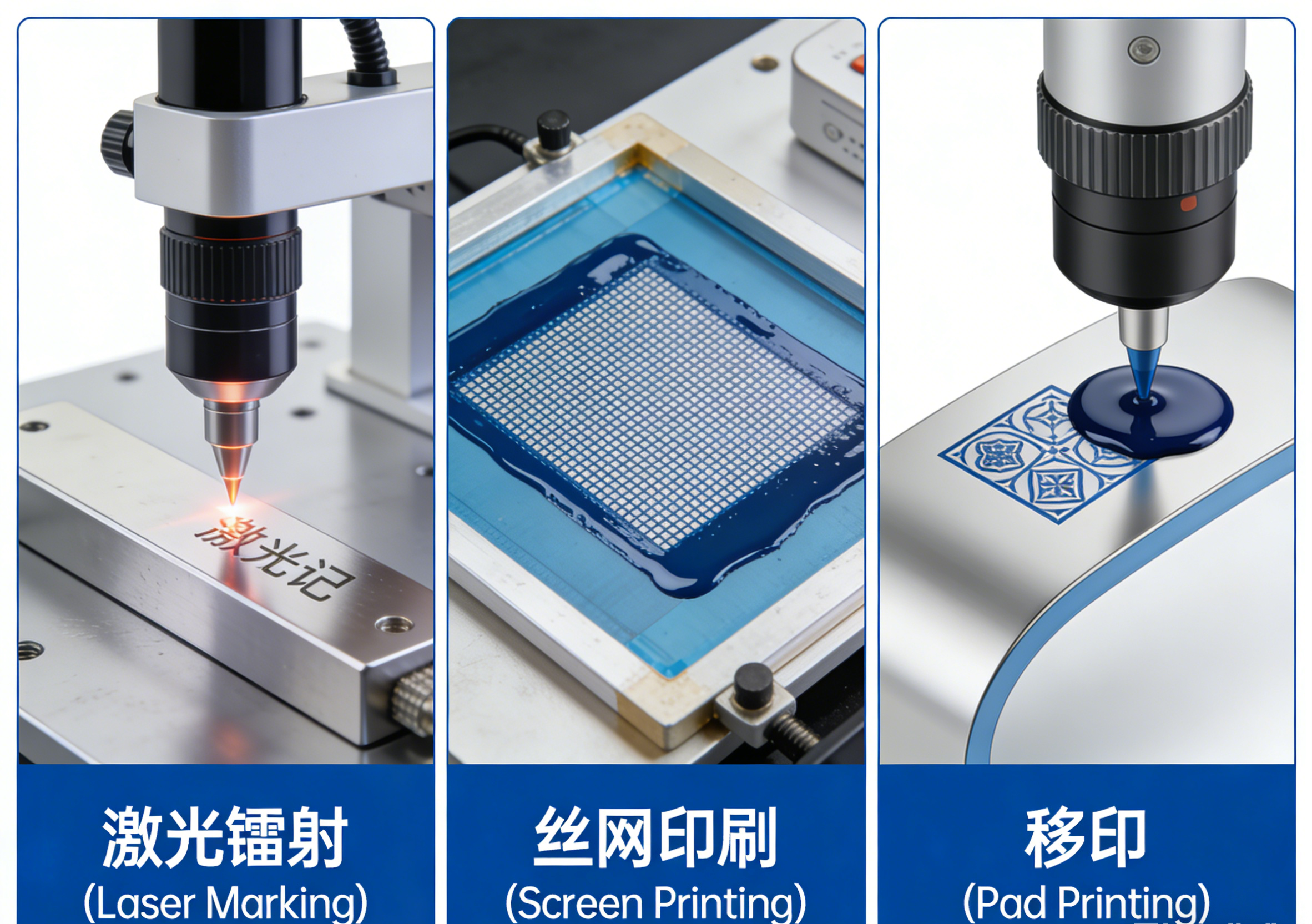

2026-01-30 When it comes to branding or adding functional markings to products, manufacturers often face a critical choice between three major processes: Laser Marking, Silk Screen Printing, and Pad Printing. Each technology has its own superpowers and limitations.

Choosing wrong can lead to faded logos, high production costs, or a finish that doesn't match your product's quality. This guide cuts through the complexity, providing a clear comparison to help you make an informed decision for your specific application—especially for injection-molded parts like your gas-assist cabinet handles.

Read More

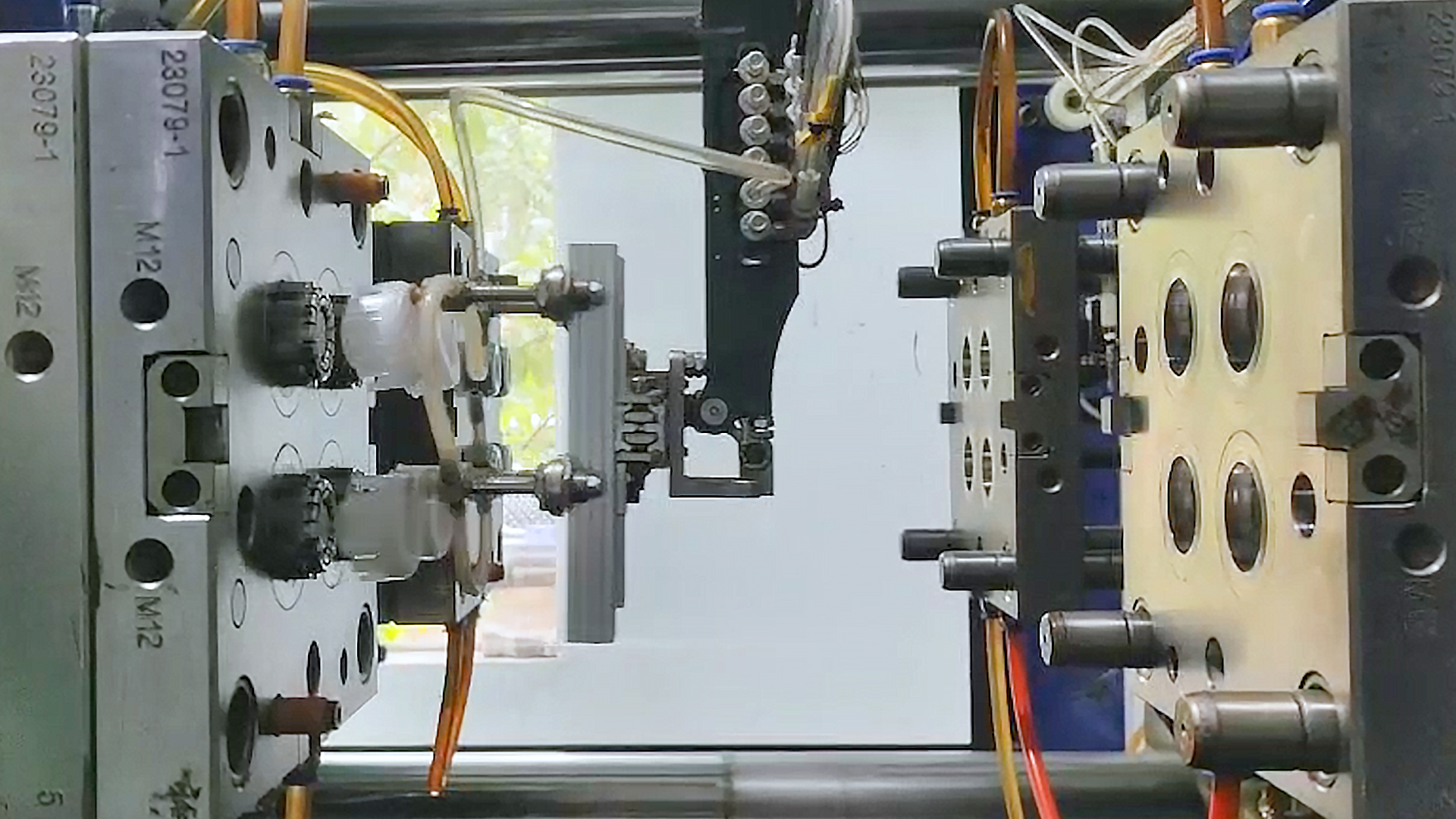

2026-01-29 You can see the main difference between two-shot injection molding and overmolding in how they make parts with different materials. Two-shot injection molding uses one machine to put two materials or colors together in one step. Overmolding puts a layer on top of a part. This is often done to make a

Read More

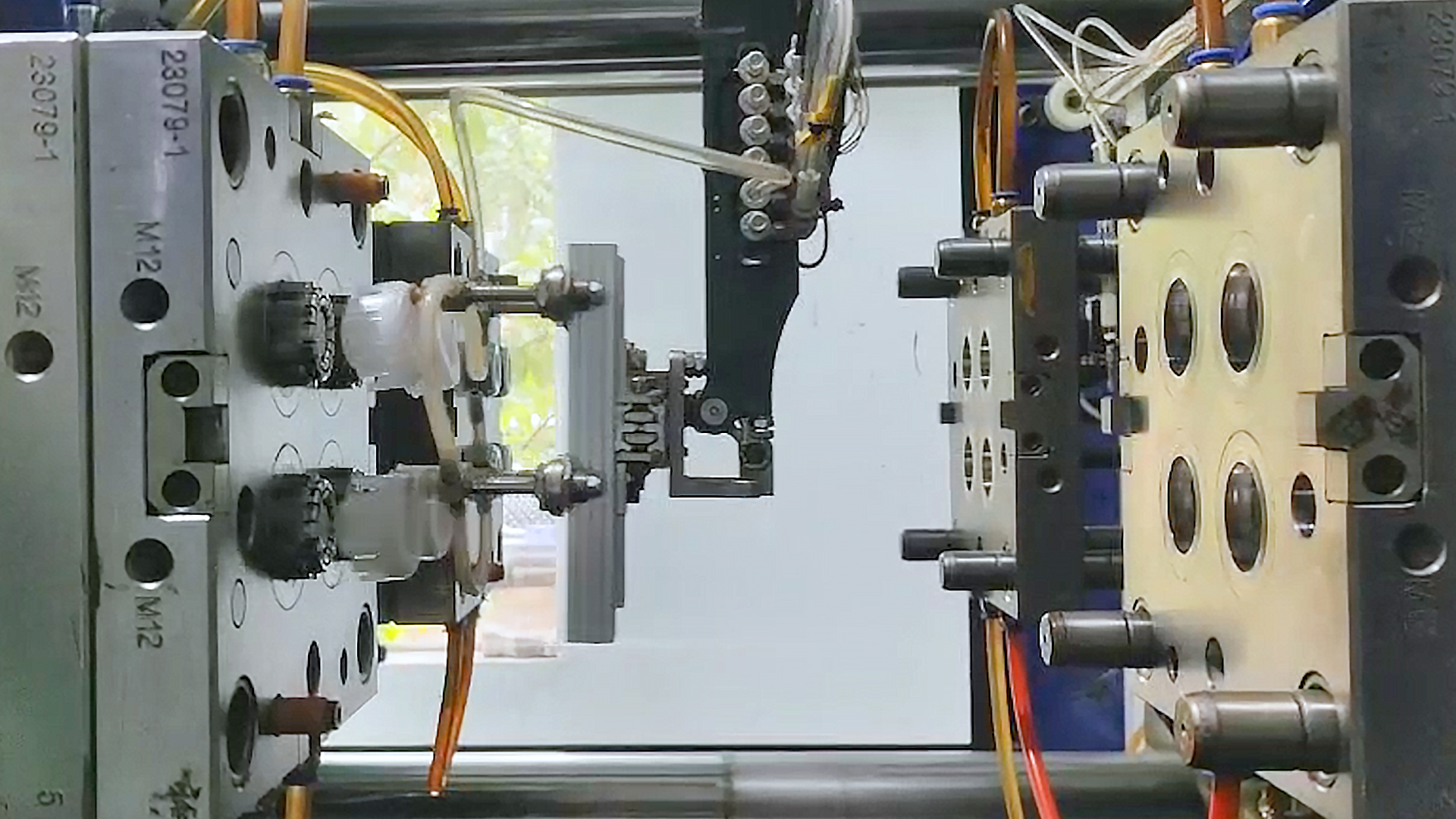

2026-01-29 Overmolding (also known as two-shot molding or insert molding) is a transformative manufacturing process that bonds two different materials into a single, functional part. From soft-grip tool handles to sealed electronic components, it delivers unmatched benefits in ergonomics, aesthetics, and performance.

However, achieving a perfect overmolded part is notoriously tricky. The process sits at the intersection of material science, precision tooling, and nuanced process control.

Here, we break down the most common overmolding challenges into four critical categories and provide practical solutions to overcome them.

Read More

2026-01-28 You can see a big difference between 1K and 2K molding. 1K uses only one material, while 2K molding utilizes two materials or colors at the same time. Picking the right process can change how well your product works and how much it costs. Think about these things when you choose a method:2K molding

Read More

2026-01-28 If you work in product design, manufacturing, or engineering, you've likely encountered two key plastic molding methods: traditional injection molding and gas-assisted injection molding (GAIM). While both produce plastic parts, they differ dramatically in process, outcomes, and ideal applications.

Let’s break down the differences to help you decide which method fits your project.

Read More

2026-01-27 You use a 2k plastic mold to join two plastics or colors at once. This is also called two-shot molding. Other names are multi-shot molding and twin-shot injection molding. With 2k plastic mold, you make things faster and save money. You do less assembly work, over 30% less. This helps you make bette

Read More

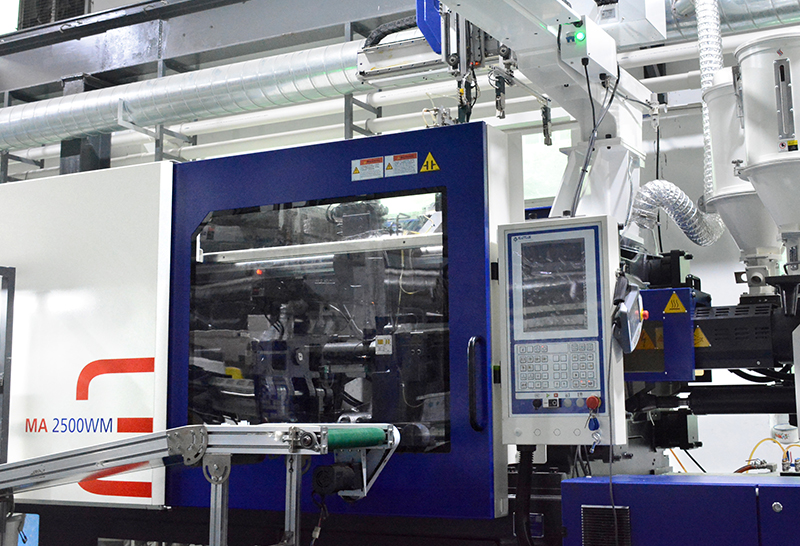

2026-01-27 Look around you. The mouse under your hand, the case of your laptop, the buttons in your car, the container in your fridge. There's an overwhelming chance these items were born from the same, transformative manufacturing process: injection molding.

It’s the invisible engine of the modern material world, responsible for producing millions of identical, complex plastic parts daily. But how can you tell if something is injection molded? What are the rules that guide engineers to choose this process over others?

This blog breaks down the definitive criteria, from high-level strategy to the "forensic" evidence left on the part itself.

Read More