| Availability: | |

|---|---|

| Quantity: | |

YIXUN mold

8480419090

Mass Production Efficiency: 4–64 cavities (customizable); cycle time as low as 8–15 seconds; output up to 100k+ parts/day.

High-Speed Performance: Optimized mold structure + precision injection molding compatibility; stable operation at 200+ shots/hour.

Precision & Consistency: Dimensional tolerance ±0.01–0.03 mm; part weight repeatability ±0.5%; surface finish Ra≤0.2μm.

Durability: Mold steel (S136/H13) with HRC 52–56 heat treatment; 1–3 million shot life (maintenance-dependent).

| Parameter | Details |

|---|---|

| Cavity Number | 4/8/16/32/64 cavities (based on part size/complexity) |

| Cycle Time | 8–15 seconds (thin-walled parts); 15–30 seconds (standard parts) |

| Dimensional Tolerance | ±0.01 mm (critical features); ±0.02–0.03 mm (general features) |

| Surface Finish | Ra≤0.2μm (matte/glossy optional); mirror polish (Ra≤0.1μm) available |

| Mold Material | Core/cavity: S136/H13 medical-grade steel; Base plate: P20 steel |

| Heat Treatment | Vacuum quenching + tempering (HRC 52–56); nitriding for wear resistance |

| Compatibility | PP, PE, ABS, PC, PVC, TPE, and medical-grade biocompatible plastics |

| Automation Integration | Robot-friendly design (ejector pin synchronization + part separation) |

Ultra-High Output: Multi-cavity design (max 64 cavities) + high-speed molding reduces unit cost by 20–40% vs. single-cavity molds.

Stable Precision: Uniform cavity cooling channels (3D-printed conformal cooling optional) + hot runner system (DME/Husky) ensure consistent part quality across all cavities.

Fast Cycle Times: Optimized mold opening/closing mechanism + shortened cooling time (via conformal cooling) cut cycle time by 30–50% vs. traditional multi-cavity molds.

Durability for Long Runs: Wear-resistant mold steel + anti-corrosion treatment (chromium plating) support 1–3 million shots without compromising precision.

Automation Ready: Integrated part ejection + separation design enables seamless connection with robots for automatic sorting, inspection, and packaging.

Hot Runner System: Balanced flow distribution (pressure drop ≤5%) to ensure uniform plastic filling across all cavities; reduces material waste by 10–15%.

Conformal Cooling: 3D-printed cooling channels (for complex parts) follow cavity contours, reducing cooling time by 40% and minimizing warpage.

Precision Alignment: Guide pins with ±0.002 mm tolerance + wear-resistant bushings ensure cavity alignment during high-speed cycles.

Quick Mold Change (QMC): Standardized clamping system enables mold change in 30 minutes or less, improving production flexibility.

Disposable Medical Supplies: Syringe barrels, infusion set components, respiratory mask parts (ISO 13485/FDA compliant).

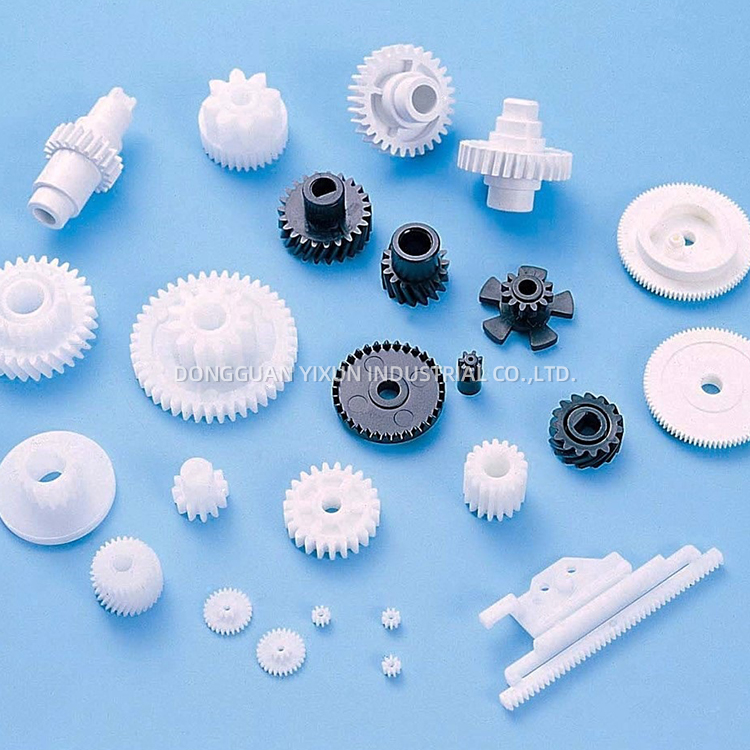

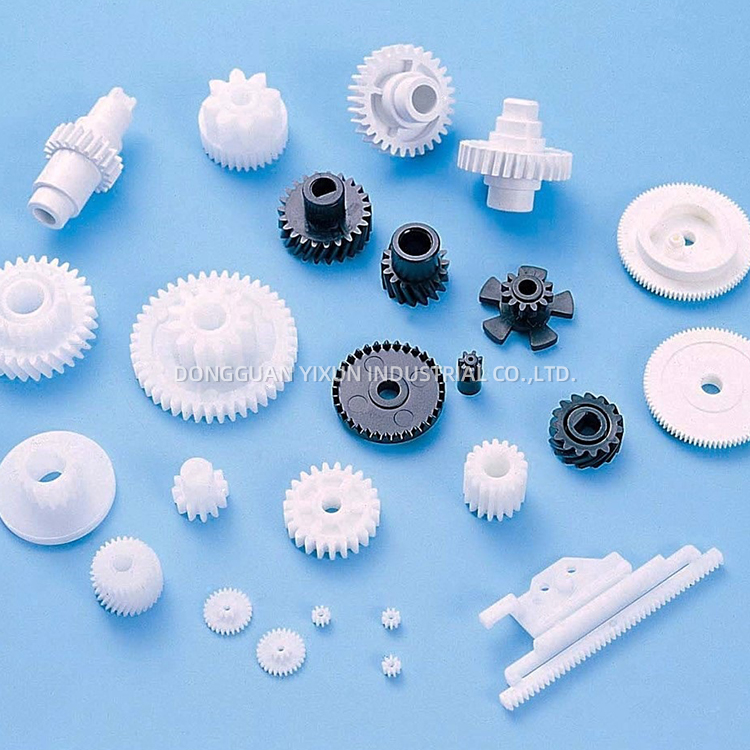

Consumer Electronics: Phone cases, charger housings, earbud shells (high-volume, consistent quality).

Automotive Parts: Interior trim clips, sensor housings, connector components (fast production for assembly lines).

Household Goods: Plastic utensils, container lids, small appliance parts (cost-effective mass production).

Cavity Uniformity Test: 100% dimensional inspection of parts from each cavity (CMM/optical measuring instrument) to ensure consistency.

Process Validation: FMEA analysis + mold flow simulation (Moldflow) to optimize filling, cooling, and ejection; stable process capability (CPK ≥1.33).

Traceability: Mold serial number + batch tracking; material lot records linked to production parameters.

Cavity number optimization based on part size (minimum part size: ≥5×5×1 mm).

Conformal cooling design for complex geometries.

Medical-grade customization (ISO 13485 compliance, biocompatible materials).

Mass Production Efficiency: 4–64 cavities (customizable); cycle time as low as 8–15 seconds; output up to 100k+ parts/day.

High-Speed Performance: Optimized mold structure + precision injection molding compatibility; stable operation at 200+ shots/hour.

Precision & Consistency: Dimensional tolerance ±0.01–0.03 mm; part weight repeatability ±0.5%; surface finish Ra≤0.2μm.

Durability: Mold steel (S136/H13) with HRC 52–56 heat treatment; 1–3 million shot life (maintenance-dependent).

| Parameter | Details |

|---|---|

| Cavity Number | 4/8/16/32/64 cavities (based on part size/complexity) |

| Cycle Time | 8–15 seconds (thin-walled parts); 15–30 seconds (standard parts) |

| Dimensional Tolerance | ±0.01 mm (critical features); ±0.02–0.03 mm (general features) |

| Surface Finish | Ra≤0.2μm (matte/glossy optional); mirror polish (Ra≤0.1μm) available |

| Mold Material | Core/cavity: S136/H13 medical-grade steel; Base plate: P20 steel |

| Heat Treatment | Vacuum quenching + tempering (HRC 52–56); nitriding for wear resistance |

| Compatibility | PP, PE, ABS, PC, PVC, TPE, and medical-grade biocompatible plastics |

| Automation Integration | Robot-friendly design (ejector pin synchronization + part separation) |

Ultra-High Output: Multi-cavity design (max 64 cavities) + high-speed molding reduces unit cost by 20–40% vs. single-cavity molds.

Stable Precision: Uniform cavity cooling channels (3D-printed conformal cooling optional) + hot runner system (DME/Husky) ensure consistent part quality across all cavities.

Fast Cycle Times: Optimized mold opening/closing mechanism + shortened cooling time (via conformal cooling) cut cycle time by 30–50% vs. traditional multi-cavity molds.

Durability for Long Runs: Wear-resistant mold steel + anti-corrosion treatment (chromium plating) support 1–3 million shots without compromising precision.

Automation Ready: Integrated part ejection + separation design enables seamless connection with robots for automatic sorting, inspection, and packaging.

Hot Runner System: Balanced flow distribution (pressure drop ≤5%) to ensure uniform plastic filling across all cavities; reduces material waste by 10–15%.

Conformal Cooling: 3D-printed cooling channels (for complex parts) follow cavity contours, reducing cooling time by 40% and minimizing warpage.

Precision Alignment: Guide pins with ±0.002 mm tolerance + wear-resistant bushings ensure cavity alignment during high-speed cycles.

Quick Mold Change (QMC): Standardized clamping system enables mold change in 30 minutes or less, improving production flexibility.

Disposable Medical Supplies: Syringe barrels, infusion set components, respiratory mask parts (ISO 13485/FDA compliant).

Consumer Electronics: Phone cases, charger housings, earbud shells (high-volume, consistent quality).

Automotive Parts: Interior trim clips, sensor housings, connector components (fast production for assembly lines).

Household Goods: Plastic utensils, container lids, small appliance parts (cost-effective mass production).

Cavity Uniformity Test: 100% dimensional inspection of parts from each cavity (CMM/optical measuring instrument) to ensure consistency.

Process Validation: FMEA analysis + mold flow simulation (Moldflow) to optimize filling, cooling, and ejection; stable process capability (CPK ≥1.33).

Traceability: Mold serial number + batch tracking; material lot records linked to production parameters.

Cavity number optimization based on part size (minimum part size: ≥5×5×1 mm).

Conformal cooling design for complex geometries.

Medical-grade customization (ISO 13485 compliance, biocompatible materials).