| Availability: | |

|---|---|

| Quantity: | |

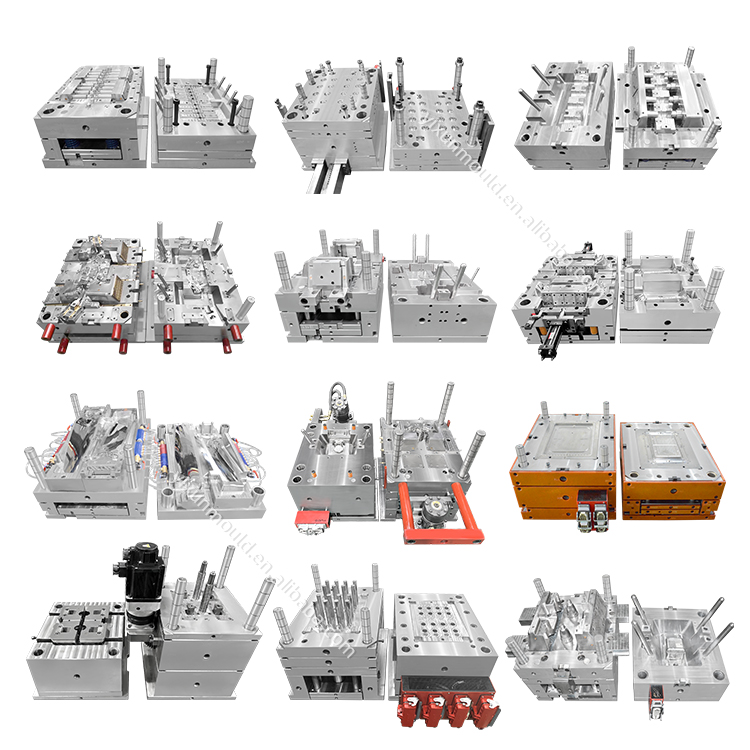

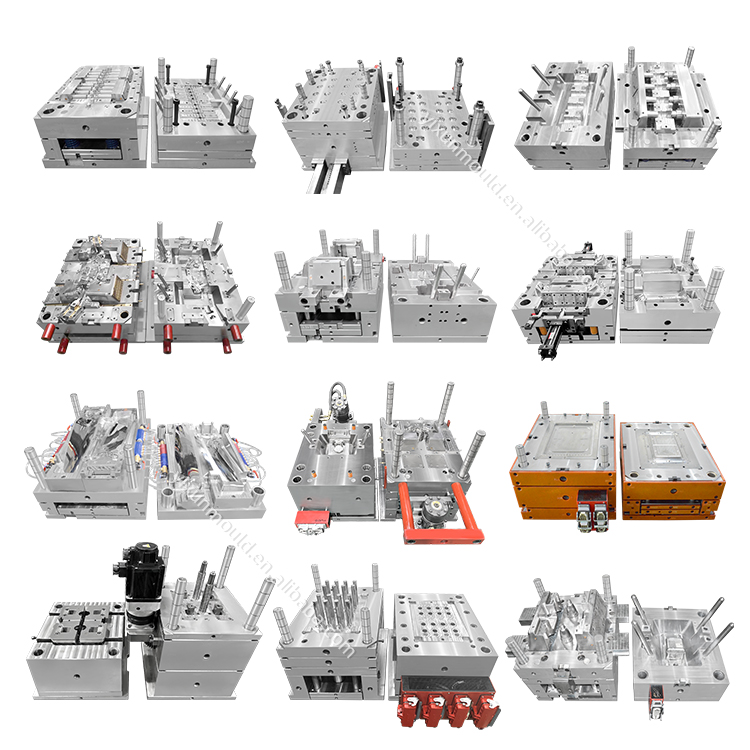

YIXUN mold

8480419090

Semifinished Product Displacement: One method is to use a mold with two cavities. The first material is injected into half of the cavities, and the second material is injected into the other half. The cavities are arranged linearly or circularly so that a displacement system or robot can move the semifinished parts from the first - half cavities to the second - half cavities. For example, in a cup mat mold, the hard - material blank is first injected, and then the soft material is injected into the reserved grooves in the second step.

Rotation: Another common form is to use an injection molding machine with a rotating table or design a rotating mechanism in the mold. The moving half of the mold rotates 90° or 180° driven by the injection molding machine. For example, in a lid mold, the moving half has a rotatable template, and the fixed half is stationary. After the first - material injection, the moving half rotates to inject the second material.

The material combinations for 2K molding are diverse. One common combination is using a hard plastic for the first injection and a soft plastic for the second, such as in products that require both a rigid structure and a soft touch. Another combination is using the same material but different colors, like in multi - colored car tail lights.

Requirement Analysis: The mold manufacturer first needs to communicate in detail with the customer to understand the product's shape, size, material requirements, production volume, and other information. For example, in the automotive industry, 2K molds for parts such as car interior trims need to meet specific aesthetic and functional requirements.

Design Optimization: The technical team reviews the customer - provided 3D model, and from the perspective of processing feasibility, proposes optimization suggestions, such as reasonable draft angles, uniform wall thickness, etc., to avoid problems like shrinkage and deformation during molding.

Precision Manufacturing: Using advanced processing equipment such as five - axis machining centers, slow - wire EDM machines, etc., to ensure the high - precision machining of the mold. During the processing, online detection equipment is used to monitor the size deviation in real - time and adjust the parameters.

Try - out and Adjustment: After the mold is manufactured, it undergoes a try - out process. The injection molding parameters are recorded, and the mold is adjusted according to the sample defects until the product meets the quality requirements.

Semifinished Product Displacement: One method is to use a mold with two cavities. The first material is injected into half of the cavities, and the second material is injected into the other half. The cavities are arranged linearly or circularly so that a displacement system or robot can move the semifinished parts from the first - half cavities to the second - half cavities. For example, in a cup mat mold, the hard - material blank is first injected, and then the soft material is injected into the reserved grooves in the second step.

Rotation: Another common form is to use an injection molding machine with a rotating table or design a rotating mechanism in the mold. The moving half of the mold rotates 90° or 180° driven by the injection molding machine. For example, in a lid mold, the moving half has a rotatable template, and the fixed half is stationary. After the first - material injection, the moving half rotates to inject the second material.

The material combinations for 2K molding are diverse. One common combination is using a hard plastic for the first injection and a soft plastic for the second, such as in products that require both a rigid structure and a soft touch. Another combination is using the same material but different colors, like in multi - colored car tail lights.

Requirement Analysis: The mold manufacturer first needs to communicate in detail with the customer to understand the product's shape, size, material requirements, production volume, and other information. For example, in the automotive industry, 2K molds for parts such as car interior trims need to meet specific aesthetic and functional requirements.

Design Optimization: The technical team reviews the customer - provided 3D model, and from the perspective of processing feasibility, proposes optimization suggestions, such as reasonable draft angles, uniform wall thickness, etc., to avoid problems like shrinkage and deformation during molding.

Precision Manufacturing: Using advanced processing equipment such as five - axis machining centers, slow - wire EDM machines, etc., to ensure the high - precision machining of the mold. During the processing, online detection equipment is used to monitor the size deviation in real - time and adjust the parameters.

Try - out and Adjustment: After the mold is manufactured, it undergoes a try - out process. The injection molding parameters are recorded, and the mold is adjusted according to the sample defects until the product meets the quality requirements.